Shanghai Meihan Intelligent Technology Co., Ltd., a national high-tech enterprise, a Shanghai specialized and innovative enterprise, and a CE and ISO9001 certified company, has been deeply engaged in the field of automated pipe welding equipment. Recently, it launched a new product - MWG-52 open pipe welding equipment. With modular design and intelligent control technology, it provides efficient solutions for welding pipes made of carbon steel, stainless steel and other materials.

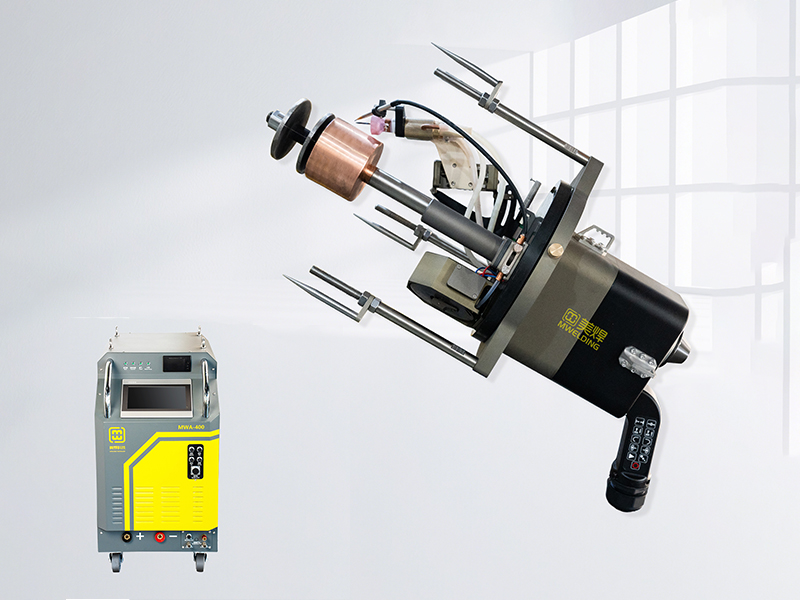

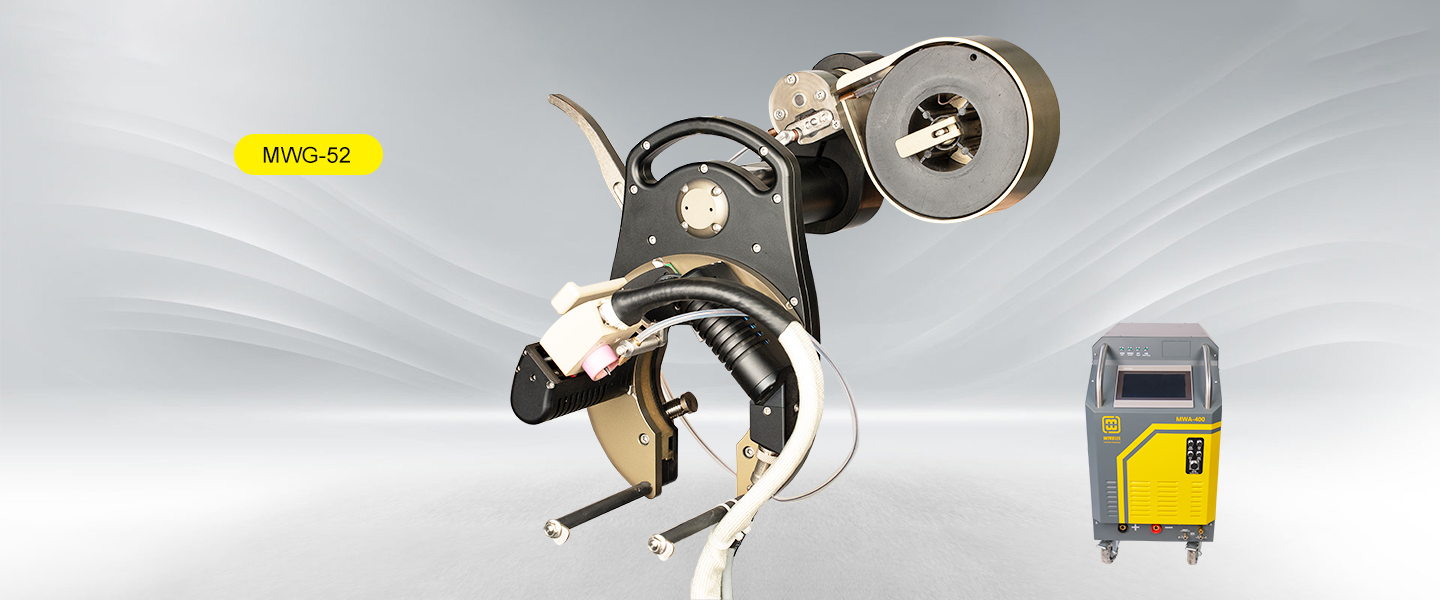

The MWG-52 complete set, consisting of the MWG-52 all-position open-type TIG pipe welding tongs and the MWA-400 integrated control power supply, offers significant advantages. The tongs, constructed of aluminum and weighing only 5 kg (excluding cable), boast a compact design. Equipped with diameter-matched clamps and a backlash-free gear drive, they offer reliable welding capabilities for pipes ranging from 32 mm to 51 mm in diameter. They also offer precise rotation speeds of 0.2 rpm to 2 rpm, making them suitable for welding medium-walled pipes from 1 mm to 6 mm in thickness. Automatic arc length and yaw control, along with a built-in wire feed mechanism, support both wire feeding and autogenous welding, meeting diverse process requirements.

MWG series open pipe welding machine for high altitude welding operation

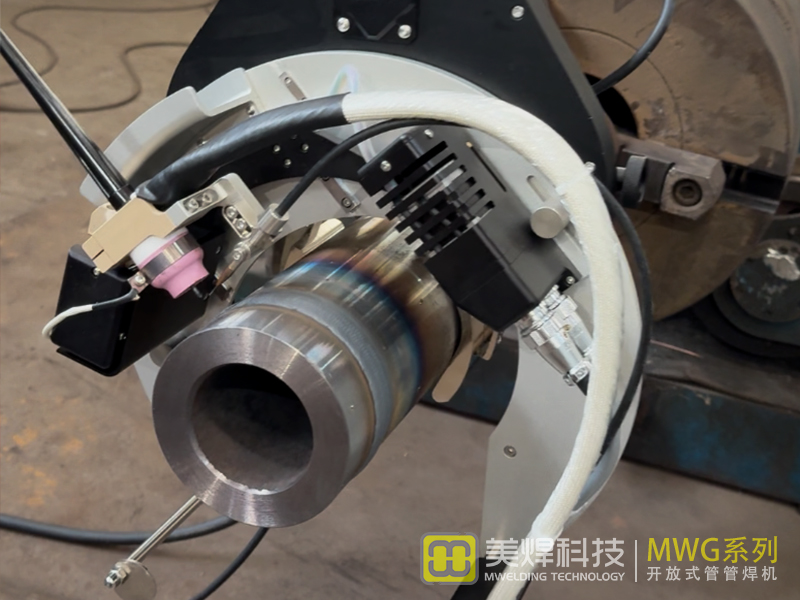

The new product breaks through traditional welding limitations, enabling all-position tungsten inert gas arc welding (GTAT) covering flat, uphill, downhill, and overhead positions. Using the MWA-400 power supply, parameters such as peak and base current can be precisely set for each position, enabling single-sided welding and double-sided welding. For easily oxidized materials like stainless steel and titanium alloys, the device also supports internal argon gas protection with a purity of 99.99%, ensuring oxidation-free welds and smooth results.

The MWA-400 integrated control power supply is the new product's "smart core". It is equipped with a 10-inch color touch screen and an intelligent PLC control system. It can monitor parameters such as current, voltage, and rotation speed in real time, supports 12 interval parameter settings and 80 sets of process code storage, and can also simulate welding processes to avoid problems in advance. It is also equipped with overvoltage, leakage, water pressure protection and an emergency stop button, providing comprehensive safety protection.

MWG series open pipe welding machine for field welding operations

The launch of the new MWG-52 not only continues Meihan Technology's precision manufacturing heritage, but also leverages its lightweight and intelligent features to lower operational barriers, improve welding efficiency, and be suitable for a variety of industrial scenarios. Meihan Technology will also provide customers with customized groove parameter solutions and on-site technical support, helping companies achieve both improved pipeline welding quality and increased production capacity.

The Meihan MWG series clamp-type automatic pipe welding machine is dedicated to delivering superior performance and value. Featuring patented technology and German component craftsmanship, it has been on the market for decades and is widely used in energy and power, boiler and chemical industries, oil pipelines, pressure vessels, and pipeline installation. Its modular design offers sophisticated design and compact structure. Its scientific and rational, steplessly adjustable clamp fully meets the pipe diameter requirements within the equipment's coverage range, effectively ensuring coaxial movement between the pipe and the welding path. It also features automatic arc length and yaw control, and can perform single-sided tungsten inert gas arc welding (TIG) root welding, double-sided forming, and achieves a weld pass rate of over 98% for Level II radiographic or ultrasonic testing. It also meets the requirements of pressure testing and physical performance testing such as impact, tensile, and bending tests.

MWG series open pipe welding machine breaks the limit and can easily weld 25mm thick pipes

1. Application industries: pressure vessels, boilers, chemical and petroleum pipeline installation, etc.

2. Scope of application: welding of stainless steel, carbon steel, titanium alloy and other materials;

3. Applicable pipe diameter:

MWG-52 is suitable for pipe diameter: Φ32-51mm, wall thickness 1-6mm

MWG-90 is suitable for pipe diameter: Φ20-89mm, wall thickness 1-25mm

MWG-170 is suitable for pipe diameter: Φ63-168mm, wall thickness 2-25mm

MWG-230 is suitable for pipe diameter: Φ89-230mm, wall thickness 2-25mm

MWG-325 is suitable for pipe diameter: Φ159-325mm, wall thickness 2-25mm

Meihan thanks you for your trust and support, and will serve you wholeheartedly!

For more products and services such as automated tube-to-tube welding machines, automated tube-to-sheet welding machines, automated girth welding machines, hot wire cladding systems, and robotic welding systems, please call: 18918961606 or visit Shanghai Meihan’s official website: https://www.mwelding.com.cn/